We owned this Desktop CNC Milling Machine for a long time. The model is Roland Modela MDX-20. It is a very old commercial model for makers and small offices. It is sad to say that it has already been stopped production. If you are lucky, you can still find a secondhand item from eBay (link). Until 3D printers became so cheap today, many hobby makers own Roland CNC machines. You may also buy a mini CNC router below USD$200 with free shipping (link). So, our tutorials may come late. But I know some junior makers receive this model (or its smaller one MDX-15) from their seniors in these few years. Some of them asked us questions via Facebook Messenger. They motivate us to write this page to share some frequently asked questions (FAQ).

- Why do we keep using this old model?

- What can you make with MDX-15/20?

- Where to download the driver/software/manual?

- Does MDX-15/20 support G-codes?

- What is the specification of MDX-20?

- How should I configure the COM port settings in Windows?

- How to cancel printing jobs?

- How to set the Z level to just above your material?

- Other tips and tricks

- Resources for MDX-15/20upgrade and development

Why do we keep using this old model?

- The first thing that we should always concern is Safety. Most low-cost CNC routers now available online are open-frame design. You should know about the dangers of rotating cutters. So, the Roland Modela series have safety design, with a safety door and protective stop. They can better guarantee you are safe. You should put your health and safety at a higher priority than your money.

- Although the MDX-15/20 has already been stopped production. Roland keeps our software and driver update for them. You don’t need to worry about the compatibility issue at this moment.

- The machine has its own CAM software to generate tool paths. This saves a lot of money to buy expensive industrial CAM software/postprocessor.

- The MDX-15/20 is multifunctional. They can also be a 3D plotter and 3D scanner (if you own the scanning unit).

- And the last reason is that it was a relatively expensive machine. We don’t want to waste it before it has to retire.

[ Back to Top ]

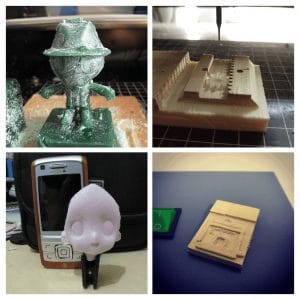

What can you make with MDX-15/20?

Here are some samples made with our Roland MDX-20.

2.5D engraving

MDX-15 or MDX-20 are 3-axis CNC machines. They can only perform a 2.5D milling by removing materials with depth. It is capable of engraving surfaces on various materials, such as wood and plastic. You can learn how to use a free Roland software, called Dr.Engrave from this tutorial on our website.

One-side or double-side 3D milling

You can fabricate 3D surfaces but limit to 2.5D profiles. For instance, it can make a half-sphere but not a full sphere at once. Instead, you have to manually flip the workpiece to profile both sides, similar to the manual duplex process in inkjet or laser printers. Alternatively, you can purchase some unusual cutting tools for side cutting. You can watch this video to learn how to cut a side slot.

Make printed circuit boards (PCB)

You can also make PCB with a Roland Modela MDX-15/20. Once you create a circuit design with Autodesk Eagle, I recommend you to output the toolpath by using opensource software, called nodela developed by Andy Sigler. The nodela supports MaxOSX, Windows, and Linux, thus I prefer it rather than another software, called fab modules designed by FabLab. The video below (by Andy Sigler) is a demonstration of milling a PCB from a Eagle file using the MDX-15/20 with nodela.

Note: This post includes affiliate links for which I may make a small commission at no extra cost to you when you make a purchase.

Related: Is Roland MODELA MDX-20 suitable for milling brass/copper parts?

[ Back to Top ]

Where to download the driver/software/manual?

You can visit this page called “Roland DGA website” on the Roland DGA website.

[ Back to Top ]

Does MDX-15/20 support G-codes?

The official answer is NO. These Roland CNC machines use a unique language called RML-1. But you can convert a G-code file to RML-1 format by using FreeCAD. There is our video tutorial about the conversion process.

[ Back to Top ]

What is the specification of MDX-20?

Please visit the page about our fabrication units -> Roland MODELA MDX-20.

[ Back to Top ]

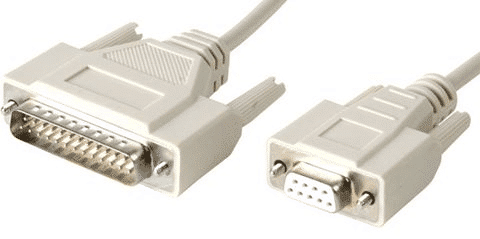

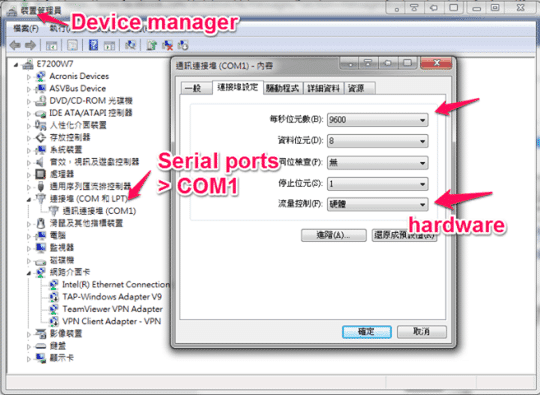

How should I configure the COM port settings in Windows?

Here we assume you are connecting the machine to an RS323 serial port. You should connect the smaller end to your computer, while the bigger end to your machine.

- Open Device Manager in your Windows OS, and find COM1 under serial ports (it can be COM2 depending on the port which you chose when you install the machine driver).

- Set the BaudRate = 9600, and Flow Control = Hardware.

MDX-15/20 uses RTS/CTS flow control. Their motherboard controls data receiving from the computer to prevent buffer overflow.

[ Back to Top ]

How to cancel printing jobs?

Enter the View mode, and then press Tool “Up” and “Down” buttons at the same time. You can find more details in this document -> [PDF].

[ Back to Top ]

How to set the Z level to just above your material?

There are two ways to leveling the z height in MDX-15/20.

Manual approach

Press the Down button on the machine. It will set Z to be zero at the last height level where you release the button.

- Pros: Simple and directly based on your eye-hand coordination

- Cons: Impossible to get exactly the same Z level, if the machine has been powered off or reset accidentally

☆Using the software developed by us☆

Using MDXLabPanel. Read the instruction from this post,

“Set or resume Z level of Roland MDX-15/20 to at the exact value you want“.

[ Back to Top ]

Other tips and tricks

📹 3 FAQs and Tips for Roland Modela MDX-15/20!

📹 Tips for Roland Modela MDX-15/MDX-20 | YouTube Playlist

Describes how to split a large NC code file into several small files, and then progressively send the NC codes to the milling machine.

To enhance the traceability of the CNC milling progress through the printer queue.

[ Back to Top ]

Resources for MDX-15/20

upgrade and development

MDXlabPanel

This is a control panel software that we develop for Roland Modula MDX-15/20.

Clamping Tool

The Roland Modela MDX-15/20 doesn’t come with jig and fixtures. To hold a workpiece on the machine table, the official manual simply recommends using double-sided tapes. But I can tell you that this way has many shortcomings. For example, it is difficult to remove the tape residues, which look dirty and make the platform uneven. Instead, I recommend you to upgrade with tailor-make clampings, such as the T-clamps designed in PCB Milling Bed for Modela MDX-20 by MosabWadea on Instructables workshop.

[ Back to Top ]

If you enjoy this post, please share it on Facebook and Twitter. You might also support us by making a donation through Ko-fi.